Organisationsänderung Turbo-Separator AG / Turbo-HKS GmbH / Turbo-Filtration Ltd. ___________________________________________________________________________________

Liebe Kunden, Partner, Lieferanten, liebe Freunde

Obwohl ich vielleicht noch nicht so aussehe, wurde ich doch im Herbst 2020, 65 Jahre alt und bin somit seit Oktober 2020 offiziell Rentner. Mein Spruch war immer, «man kann als CEO in Rente gehen, als Eigentümer aber nicht». Und doch ist es Zeit, dass man sich überlegt, wie es künftig weitergehen soll. Gerade die letzten Jahre haben viel von uns abverlangt, Kundenbesuche und Besuche der Tochterfirmen waren durch die COVID-Restriktionen fast unmöglich. Diese speziellen Jahre haben uns zur Einsicht gebracht, dass es gerade jetzt an der Zeit ist, jüngeren und vor allem fitteren Leuten das Steuer der Turbo-Gruppe in die Hände zu legen. Es ist somit für mich die Zeit gekommen, nach mehr als 22 Jahren, die operative Verantwortung weiterzugeben.

Was mich besonders freut an dieser Abgabe der Verantwortung ist, dass es unsere beiden Kinder sein werden, die diese Verantwortung gemeinsam mit einer stark verjüngten Geschäftsleitung übernehmen werden. Gemeinsam haben sie beschlossen die Firma in der bewährten Weise weiterzuführen.

Gegen Ende des Jahres 2022, werden folgende Veränderungen umgesetzt sein:

· Offizielle Einsetzung der Co-Geschäftsführung unserer beiden Kinder Sarah und Tobias, aufgeteilt in Administration und Technik, aber gemeinsam bestimmend und verantwortlich.

·

Rückzug von Ruedi Bannwart aus dem

operativen Geschäft, sowie schrittweiser Rückzug meiner Frau Eveline als

Finanzchefin, jedoch werden wir auch weiterhin als Supervisor und im

Verwaltungsrat tätig sein.

· Die Eigentumsverhältnisse der gesamten Gruppe bleiben bestehen.

Unsere persönliche Meinung ist, dass für ein «Neuanfang» auch ein Bruch mit der Vergangenheit notwendig ist und dass bei einem solchen Manöver auch die alten Chefs ausscheiden sollten. Wir werden aber weiterhin im Verwaltungsrat und als Eigentümer und damit als Supervisor für die Leitung der Firmen, verfügbar sein. Wir werden dies aber nur dann wahrnehmen, wenn uns die neue Leitung und/oder der Verwaltungsrat dazu auffordert.

Durch diese Neuorganisation ist eine stark

verjüngte Geschäftsleitung entstanden, die aus allen Prozessverantwortlichen

besteht - Finanzen, Verkauf, Service, Produktion und Technik. Die bis heute

bewährte Crew wird sich als Coach und Mediatoren sicher gut bewähren und für

einen guten Übergang und eine gute Weiterentwicklung Sorge tragen.

Wir sind zuversichtlich, dass diese, unsere Entscheidung eine nachhaltige und zukunftsweisende Entwicklung ermöglicht, die zum Wohle der Firma, und deren Partner, beitragen wird.

In diesem Zusammenhang möchte ich Ihnen, liebe Freunde und Partner, danke sagen für viele Jahre gute Zusammenarbeit, Treue und wohlgesinnt sein. Es war eine schöne Zeit und ich werde diese vermissen. Wir werden uns sicher irgendwann, irgendwo wiedersehen, denn, ich bin immer noch «Turbo».

Ich wünsche mir und davon bin ich überzeugt, dass

Sie unserer neuen Leitung dasselbe Vertrauen und Wohlwollen entgegenbringen,

wie Sie es mir angedeihen liessen.

Denn eines ist mir besonders wichtig, Partnerschaften werden zwar auf Menschen, aber nicht auf einzelne Personen aufgebaut. Somit danke ich Ihnen auch für eine fortwährende Partnerschaft.

Besten Dank für die lange und gute Zeit

Euer Ruedi Bannwart

Am 1. Oktober 2000 trat unser Eigentümer als Geschäftsführer in die Turbo-Separator AG ein. Fast gleichzeitig mit seinem 65. Geburtstag konnte er also am 1. Oktober sein 20. Firmenjubiläum feiern. Doch nicht genug der Jubiläen. Ebenso in diesem Jahr konnte er 15 Jahre Geschäftsführer bei der Turbo-HKS GmbH Gottmadingen und 10 Jahre als President bei der Turbo-Filtration Ltd. Shanghai feiern. Das dies ein Fest werden sollte ist klar. Die beiden jungen Mitarbeiter Fabian Fröhlich (QM) und Tobias Bannwart (GL-Assistant) haben die Gelegenheit gepackt und einen wundervollen Anlass in den Räumlichkeiten der Turbo-Separator AG organisiert. Besten Dank dafür. Eine Powerpoint Demo über die 20 Jahre Turbo und ein eigens vom chinesischen Büro erstellten Film mit Gratulationen der Mitarbeiter und Kunden aus China haben ein ebenso freudiges wie emotionales Bild dargestellt

Der kurze historische

Rückblick zeigt, was wir in dieser Zeit geschaffen haben.

2000: Übernahme der Geschäftsführung der Turbo-Separator AG durch R. Bannwart

2005: Übernahme der HKS Technology GmbH in Singen und Integration als

HKS-Filtration-Technology GmbH

2008: Ausbau der Lokalität in Wattwil durch einen Neubau für die gesamte Produktion

2010 Gründung der Turbo-Filtration Science&Technology Co. Ltd. in

Shanghai als Verkauf und Servicebüro

2013 Tod unseres früheren Eigentümers

und langjährigen Begleiters der Turbo, Dr. Walter Ruf

Übernahme von 67% der Firmenaktien der Turbo-Gruppe durch R. Bannwart

2014 Verschmelzung der ehemaligen Turbo-Separator GmbH und HKS

Filtration-Technology GmbH zur neuen

Turbo-HKS GmbH

2016 Neubau des Verwaltungstraktes in Wattwil und Zusammenführung der Firma an einem Ort

2018 Straffung der Gesamtorganisation durch Reorganisation der Firmen Turbo-HKS GmbH zu einer Verkaufs- und Serviceorganisation und der Turbo-Filtration Ltd. durch ein lokales Management.

Also genügend Gründe für ein Dankeschön an die Mitarbeiter.

Für Speis und Trank waren die APE STREET BAR und die Gruppe des BBQ-Sheriff verantwortlich.Einfach Danke sagen

Ich danke allen die mir in dieser Zeit Halt und Unterstützung und ihre Freundschaft gegeben haben, denn eines weiss auch ich: Allein kann und hätte ich das nie geschafft. Einschliessen möchte dabei auch unsere Lieferanten und Kunden, denn gerade sie sind ein essenzieller Teil dieser, meiner Entwicklung. Ein ganz spezieller Dank geht natürlich an meine Familie und da ganz besonders an meine Frau die zusätzlich in den letzten 8 Jahren als Finanzchefin der ganzen Gruppe, mir die Möglichkeit gegeben hat diesen Job so auszuführen wie ich ihn gemacht habe.

Eines sei noch gesagt, Rentner

heisst nicht pensioniert zu sein, denn als Geschäftsführer kann man jederzeit

aufhören, als Eigentümer bleibt man auch darüber hinaus mit der Firma

verbunden.

Also denken wir an die Zukunft, machen wir was daraus.

Ruedi Bannwart

Nach sorgfältigen Überlegungen haben wir beschlossen an keiner Messe im Jahr 2020 auszustellen. Diese Entscheidung ist uns nicht leichtgefallen, jedoch räumen wir der Gesundheit unserer Kunden, Mitarbeitern und Messebesuchern Vorrang ein. Die durch die Pandemie vorherrschende Unsicherheit und die bestehenden Reise-

Beschränkungen haben zum Verzicht auf die Messeteilnahme geführt. Wir werden die vielen guten Gespräche vermissen, möchten Sie jedoch auffordern uns anzurufen und uns zu besuchen. Unser Haus ist jederzeit offen und wir sind gerne für Sie da.

Bleiben Sie gesund.

Ihre Partner und Freunde der Turbo-International Gruppe

After careful consideration we have decided not to exhibit at any exhibition in 2020. This decision was not easy for us, but we give priority to the health of our customers, employees and visitors. The uncertainty caused by the pandemic and the existing travel restrictions have led to the decision not to participate in the trade fair. We will miss the many good conversations, but would like to invite you to call us and visit us. Our house will always be open and we are happy to be there for you.

Stay healthy

Your partners and friends of the Turbo-International Group

Filter technology in dependence of cooling lubricants

Read the article in Original on our linkedin Page:

Many of our customers think that there is one cleaning system for every application. Unfortunately, there is no such thing as the all in one device suitable for every purpose or how we like to call it this egg laying woollen milk sow. In order to be able to offer customers the best possible solution, all relevant influencing variables on the cleaning must first be defined. First of all, I would like to say a few words about the classification of cooling lubricants.

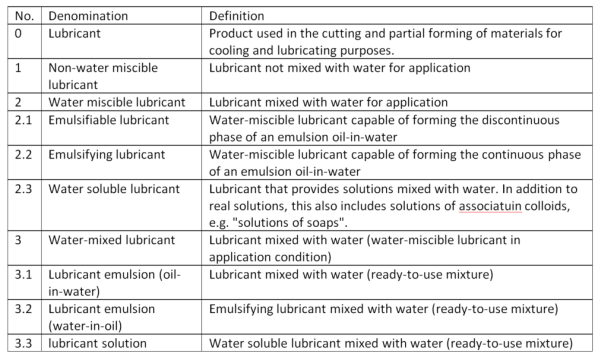

Classification of cooling lubricants

We distinguish cooling lubricants into water-miscible and

non-water-miscible cooling lubricants. The DIN standard has published a

list of cooling lubricants, which is listed in Table 1.

By this classification it can be recognized that most cooling lubricants are covered. What is not listed here, however, is the explicit representation of water. Most people know that in some cases water is one of the best coolants imaginable. One can of course point out that water alone is too aggressive and has too little lubricity. Right, but the cooling effect is ingenious and with new materials like glass and ceramics or any composite materials water can be a very good, if not the best solution.

But what are all the factors that influence the cleaning process?

This article should answer this question and also show you what are the most important factors for us on the cleaning process

Influencing factors on cleaning

For us, there are several aspects that have a very large influence on the type of filtration and the quality of the results. The first is the viscosity of the cooling medium, but also the type of dirt carrying behavior which can strongly influence the filtration. In addition, the processing material and the necessary purity must also be taken into consideration. Not to forget the cutting tool. We have often experienced that changing the cutting tool can cause unexpected problems in filtration.

For an optimum cooling and lubricating effect in any type of machining, we must also consider the additives that strongly influence this effect. The manufacturer of the cooling lubricant can explain the exact properties of various additives to you in more detail.

The topics I would like to take up and explain here are the following: viscosity of the cooling lubricant, processing material, necessary purity of the medium, dirt carrying behavior and sludge treatment.

Viscosity of the cooling lubricant

Definition: Viscosity is the property of a liquid to resist the mutual laminar displacement of two adjacent layers.

Dynamic viscosity η = Shear stress τ / Speed gradient D [Pa * s = Ns/m2 ]

Kinematic viscosity ν = Dynamic viscosity η / Density ρ [mm2 / s = cSt]

We usually know the kinematic viscosity, which influences the flushing, the cooling, but above all the functionality of a cooling lubricant. When and which viscosity is desired. This can be roughly explained as follows. In a type of forming (honing), high-viscosity lubricants are used above all, while low-viscosity lubricants are used in cutting operations.

Dirt carrying capacity

Through the optimum use of additives, a cooling lubricant can be modified accordingly, but this also means that the behavior can be completely reversed. If you go to your oil supplier and tell him that your machine is very dirty, he will suggest a solution by changing the wear behavior of the medium by adding additives. It is less sticky but more carrying. This means that your medium can better transport the dirt particles to the cleaning system. However, it is also possible that the change in the wear behavior will make it more difficult for the cleaning system to separate the dirt particles from the medium again.

The added additives combine better with the dirt particles, increase the surface area and thus reduce the specific total weight and make it float better.

The dirt particles behave like an egg yolk, which is difficult to separate from the protein. Such a dirt particle is more difficult to separate in almost every separation process, or a lot of liquid is carried out.Material to be processed

Almost every filter system has its own specialties, where it works well, very well or also very badly. Of course, it cannot be assumed that the filter systems can easily be assigned to a material or a type of processing. This has to do above all with the fact that all these influencing variables can and do influence each other. The material is rather tough or brittle, especially when grinding, there are very different chip shapes and sizes. This influences the filter types accordingly. Whether one grinds carbide, high-alloy steel, aluminum or non-ferrous metals, or what their grinding process looks like, the chip shape will also change and thus also influence the type of filtration.

Example: We have a customer who is a tool grinder, in total five identical machines are running. All plants run with the same oil, all produce with the same materials, all machines run 24 hours a day. Four machines run with the same grinding wheels and have the same grinding procedure. A process also has the same grinding wheel, but this one is crushed instead of dressing and has a different relative grinding motion.

The existing filtration is therefore suddenly no longer sufficient. The chips are much finer and the shape of the chips is completely different.

Plate chips (carbide) can be removed very well with filter cartridges, so-called backwash filters. HSS chips (gear wheel grinding) are very woolly chips and immediately clog such filters. Such woolly chips can be removed very easily with belt filters, but glass chips clog the belt filter immediately. The dependency cannot simply be attached to one of these parameters. The interaction of all parameters results in the optimum type of filtration.

What is purity?

We live in a time, in which progress makes uncanny steps, in former times we were still content, if we had to change the emulsion once in the month, today a tendency to perfectionism is to be recognized. We always ask ourselves if this is necessary.

What is the purity of a medium - what do we understand by it?

Statements like:

- We need a purity of 1 µm.

- The oil must be as clear as new

- The liquid must not discolor

- The emulsion must be white

Aren't there really any help

The statement: "Clean" is as relative as everything we do.

To be able to measure cleanliness, a standard is used here that actually has nothing to do with processing. These standards actually apply to hydraulic oils. We are talking here about DIN ISO 4406 1999. This method also gives us no certainty that we will find the one µm. We are fishing in the truest sense of the word. Let us therefore give you a definition that is individual, but certainly applicable to everyone:

It is pure if:

- The critical parts are removed

- The cooling medium is not damaged

- The result is sufficient for the process

- The machine is not unnecessarily dirty

- No residues are visible optically

- The cleaning system is still affordable

That is:

- Everyone defines his own purity

- Depending on the process & own perception

Conditions must be examined and adapted to the process.

Unfortunately, there is no perfect solution for every application, every customer, every material and every liquid.

The manufacturer and the producer must work together to find the optimum solution for the customer's specific cleaning problem. Our concern is to show our customers why we propose a solution. We don't just want to sell products, we want to give the customer a solution that optimally supports him in his process and guarantees the process security.

How do companies worldwide manage the cleaning of industrial fluids? 29.10.2018 TOBA

While all over the world there is a discussion of how to reduce waste, this is hardly happening in industry. Negotiations are underway as to whether straws should be banned, whether cotton swabs should no longer be sold or how environmentally damaging cardboard cups are. Until a few years ago, the processing of industrial liquids was not very widespread outside Europe. Today, however, more and more companies around the world are demanding that contaminated liquids needed to be treated. When treating industrial liquids, a general distinction is made between two different types of filter. Cleaning with industrial filters which, however, require filter aids and consumables. The second types are filtration methods without consumables.

With consumables

With the help of consumables, filters are also used in industry to ensure filtration. In most cases, however, it is not only the type of filter or the condition of the filter that is decisive in this type of filtration. In a filtration process using a belt filter, an additional filter cake builds up on the flow which is the actual filter. This has the consequence that with a perfect filter cake, the purity can be increased. Industrial filters work very similar to filters that are commonly used in private households. The big difference is the filter performance.

As with other filtration methods, there are different types of filters with consumables, but they are always built according to the same principle of filtration. A positive aspect of industrial filters is the lower investment cost than filtration without auxiliary equipment.

Without consumables

This type of separation of liquid and solid is ensured by centrifuges. When separating liquid and solid by usage of centrifuges, it can only physically function if the two substances have different specific densities. Liquid separation can be imagined as sedimentation in an open container. The greater the delta of the two densities, the faster the heavier material settles at the bottom of the container. This sedimentation is also used in the centrifuge, but the liquid is accelerated in a drum to accelerate the natural sedimentation many times over. This type of filtration is more expensive than filtration with consumables. However, these investment costs can be offset by long running times and also by turnover calculation because of the consumables.

Combination

More and more often not only a belt filter or a centrifuge is required. More and more often, complete plants are required, which require combinations of both types. These plants can combine the best of both types to increase sustainability and process reliability in industry.

Centralized Systems

More and more companies in industry do not want a single cleaning system at every processing plant. They demand that central plants are built which have more flow and the cleaning quality is nevertheless constant. This means even higher investment costs for the companies, which will be worthwhile after some time.

Thanks to these possibilities of cleaning liquids, with the help of other cleaning methods, the life expectancy of industrial liquids can be increased many times over. Whenever companies need normal water and no oil or oil-water mixture, this purified water can easily be returned to rivers after continuous testing. This protects the environment and water can be reused more frequently. The challenges in cleaning these fluids are often that companies want cleaning for a variety of applications in a single plant. Since chips or abrasive removal behave differently in different fluids, each application must be individually tested and designed for process engineering. These cleaning systems are not only to be found in Europe, they are increasingly being sold in the Asian region. The regulations in the Asian region regarding the disposal of industrial liquids are becoming more and more similar to the European regulations, in some cases even more stringent. This development helps to constantly reduce the pollution of public waters.

Unfortunately, many companies see investment in the cleaning and reprocessing of industrial fluids as a forced investment. This although, causes a safe process, longer service life and less cost. Cleaning industrial fluids not only has a positive effect on the environment, but also helps companies guarantee a stable process.

To sum it up, although there is often no discussion about it, waste treatment in the industry, many companies are already aware that something needs to be done in this area. Grinding machines can hardly be bought without a cleaning system for the cooling lubricant. Unfortunately, however, there are still many companies that are not interested in the serious cleaning of cooling lubricants. In the future, the aim for companies should be to set a good example and take the environmental compatibility of their production even more seriously. To change the industry now and in the future, this is our goal; we help to reduce the constant contamination, because we build centrifuges and filtration system for more than 60 years.

Turbo-Separator AG Bleikenstrasse 48 CH-9630 Wattwil

The Turbo-Separator AG presents its new concept, modularity - flexibility - design, at the EMO in Hannover

Organizational change in the sales organization of the Turbo-Group

The market is changing, we take these changes as an opportunity and adapt our organization. According to our motto that we are the problem solvers on site, as a manufacturer or as a general contractor, we realize, that we are increasingly asked for group or

central systems. We take this trend into account by providing engineers for two special areas, which, together with our regional salesman, plan the optimum solution for you, our customers. The sale has therefore been reorganized.

New: Leader application technology - Mr. Darius Pechta

Our current sales manager, will, in addition to the management of his sales region, leads the Management of application technology for medium and large plants. To give him the necessary capacities for this new task, he draws back as Sales manager from 1 July 2017. It will continue to be the key account for specific OEMs.

New: Leader eyeglasses technology and optics - Mr. Bernhard Welle

Mr. Bernhard Welle has been active for many years in optics and especially in the Eyeglasses technology. These tasks take besides the supervision on the international sale and , the care of agents, etc. are always a bigger one Scope. For this reason he is also from the direct management of the sale excreted. He will be active in the area of optics as head of spectacle glass technology.

New: Sales Manager - Mr. Claudio DeFilippis

Mr Claudio DeFilippis joined our company two years ago. In this time he made the Sales in Switzerland again to what we expected of it. At the same time, he developped the Sales in the south regions, especially Italy and France. Through his secondary education as sales manager, he is the right man at this time to take responsibility as a sales manager of the Turbo group.

Inauguration of the newly built office floor and anniversary celebrations for the 60th anniversary of Turbo-Separator AG