The compact systems are usually placed directly next to the processing machine. From the machine, the KSS runs directly or via lift pumps to the processing plant. There, the contaminated coolant is cleaned and cooled with centrifugal separators and / or filters. The machine is supplied with the desired quantity and pressure from the integrated tank of the system.

From 2018

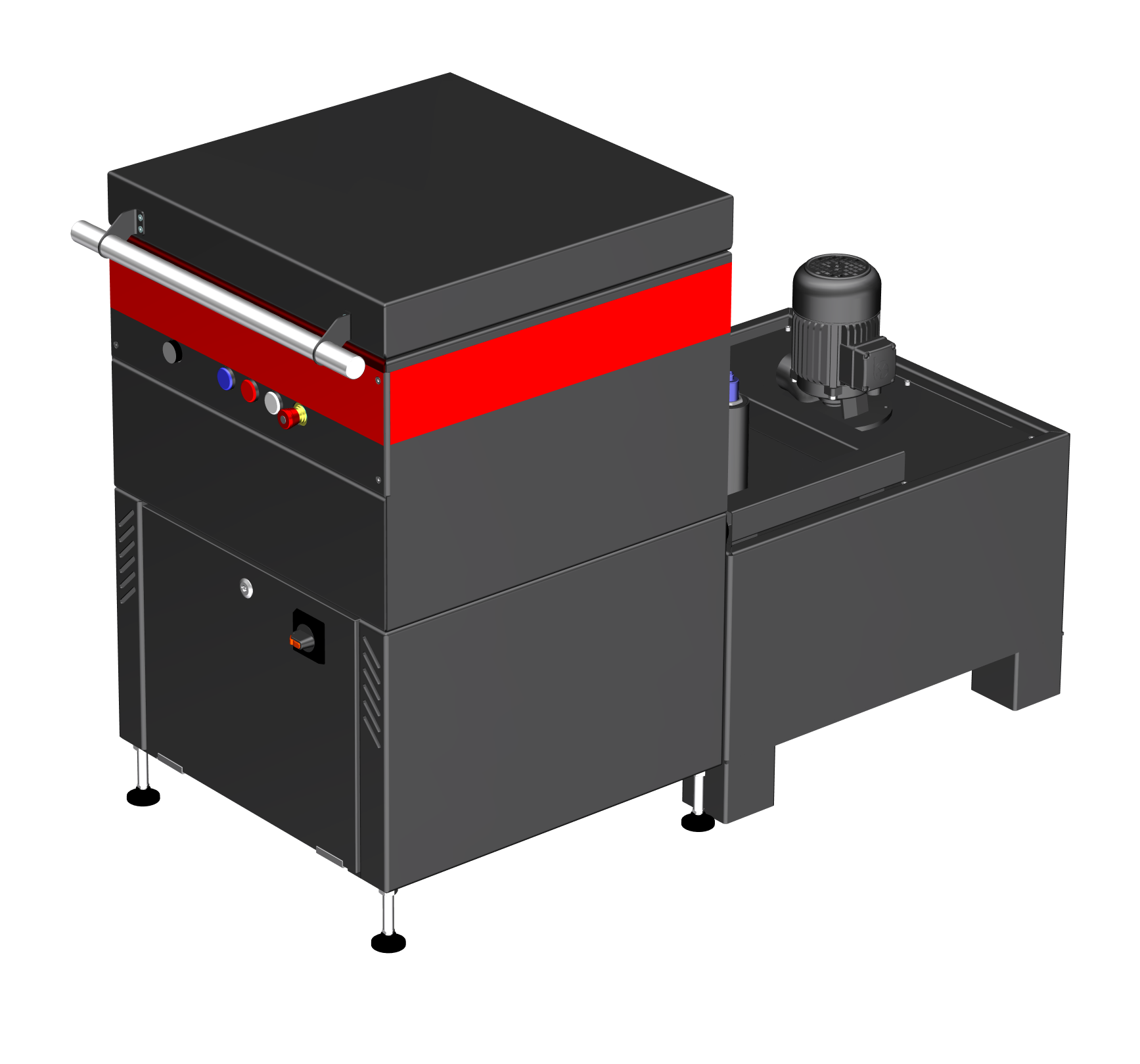

NGU-200Characteristics

- Manual Centrifuge

- Cleaning Performance up to 1-120 l/min Oil 1-140 l/min Emulsion

- Rotor capacity appr. 22 Liter

- Manual sludge volume up to 10 kg

Downloads

MZF-T06/07

Characteristics

- Manual Centrifuge

- Cleaning Performance up to 30 l/min Emulsion/Oil

- Rotor capacity appr. 6 Liter

- Manual sludge volume up to 2-3 kg

MZF-T10

Characteristics

- Manual Centrifuge

- Cleaning Performance 80-100 l/min Emulsion/Oil

- Rotor capacity appr. 10 Liter

- Manual sludge volume up to 3-5 kg

MZF-T22Characteristics

- Manual Centrifuge

- Cleaning Performance 120 l/min Emulsion/Oil

- Rotor capactiy appr. 22 Liter

- Manual sludge volume up to 10 kg

MZF-T14Characteristics

- Manual Centrifuge

- Cleaning Performance 1-150 l/min Emulsion/Oil

- Rotor capacity appr. 14 Liter

- Manual sludge volume up to 10 kg

The mobile ones

For customers who want to go from machine to machine and clean their coolant, Turbo offers the T06, and the T14 also as a mobile version and the necessary pumps.

For customers who want to go from machine to machine and clean their coolant, Turbo offers the T06, and the T14 also as a mobile version and the necessary pumps.

Downloads